The Red Sea Robotic Exploratorium

Enabling Intuitive Underwater Telemanipulation

The Red Sea Robotic Exploratorium is one of the major collaborative projects done in the lab involving parties from academia and industry. The main aim of the project is to bring together roboticists and marine scientists to develop a novel framework for underwater telemanipulation at the Red Sea.

Lying between Africa and Asia, the coastal zone of the Red Sea is an ecologically unique marine ecosystem that houses one of the most extensive, diverse, and colorful coral reefs in the world. The coral reef, with its many endemic species of marine invertebrates and fish, provides a vital research platform for studying how humans impact marine ecosystems.

Exploring and monitoring these oceanic resources, however, has remained expensive and challenging because it requires human divers who can only explore these environments during short periods of time and within limited depths. While underwater vehicles have proven to be very useful for safely exploring oceans at greater depths, they lack human dexterity, which is necessary for performing fine manipulation tasks like collecting reef samples. Furthermore, existing underwater robots are large and cumbersome, with mechanical characteristics that make them extremely difficult to operate in closely confined fragile spaces or turbulent fluid environments.

As a part of the KAUST Global Collaborative Research Program, Stanford University is part of a team of universities working to build a major science and technology university along a marshy peninsula on Saudi Arabia’s western coast. Meka Robotics (currently with Google) joined the collaboration and provides the hardware for the development of dexterous underwater robot arms.

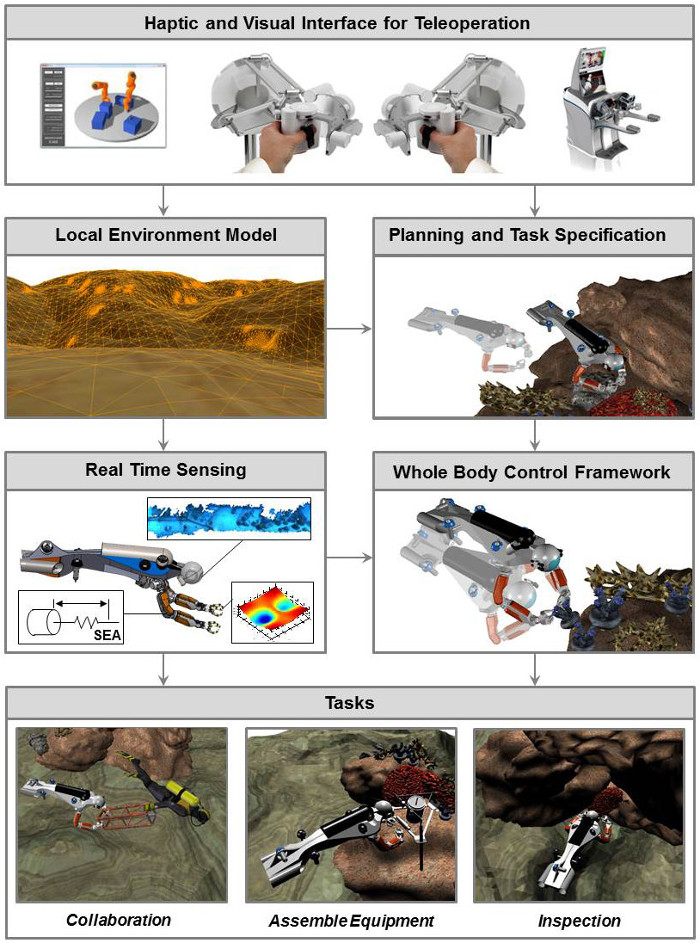

To help marine biologists safely explore the Red Sea’s fragile and previously inaccessible underwater environment, our team designs a semi-autonomous underwater robotic explorer. The new vehicle will visually explore and image the sea, collect samples, perform manipulation tasks using flexible fingers, and conduct various physical measurements in multiple marine ecosystems. The robot will combine two force-controlled lightweight arms that will be remotely operated using an intuitive two-handed haptic interface providing force-feedback guidance to the operator while the posture of the vehicle body is controlled autonomously.

This allows us to use the underwater rover for bimanual haptic tele-manipulation. As an interface between the human operator and the controller, two Force Dimension Omega 6 haptic devices as shown above were integrated. Given the complexity of optimizing the final vehicle, a small underwater vehicle serves as a platform to test many of the operations the final vehicle is expected to perform.

Project Overview

Control System Architecture

Hardware Design Overview

Arm Design

Designing a compact and light weight arm for underwater purposes is non-trivial considering the additional requirements of sealing and pressure compensation. Several experiments were conducted with a custom-made pressure pressure chamber to explore various ways of sealing and to investigate their impact on motor performance, joint friction and torque sensing performance. The insights gained were then assimilated into the design of a 2-dof bicep module of the robot arm.

With the 2-dof prototype completed and tested, we proceeded to analyze and determine the overall configuration of the arms with respect to the robot. We ran simulations and and characterized both static and dynamic requirements that is needed so as to proper macro-mini coordination between the arms and vehicle. Currently, we have completed the full design of the arms and are in the process of fabrication. We are also running stress tests on the electronic components and writing control softwares for the arms.

Hand Design

The hand design is done in collaboration with Professor Mark Cutkosky's group at BDML. Hands are one of the most critical components when it comes to manipulating delicate live specimens, like deep-sea sponges; collect coral samples using a chisel and hammer; deploy and position long-term sensing equipment or structures; retrieve samples below overhangs and in crevices; and, operate tools designed for human divers. Therefore, it is essential to design and come up with software tools to analyze various grasp configurations and establish a optimal design. One of the main challenges of the hand is the compact packaging of all the electronics and motors into a watertight compartment. The use of 3D printing enabled quick design iterations and tests. Currently, we are in the process of building the final design. Concurrently, we are also looking into novel ways of integrating tactile perception and displacement feedback with high-level manipulation primitives on the haptics teleoperation interface.

Full System Design

The design of the entire arm-vehicle system is non-trivial since it involves the integration of all electromechanical components with our proposed control architecture. We adopted a top-down approach, relying on our custom-designed simulation tools and previous research on whole-body control framework to place components and determine the required sensor suite for the robot. This design methodology banks of the concept of "design for control" where we start from all the required task specifications of the robot and move upstream to the specification of the arms' actuators, vehicle's thrusters and body structure. Currently, we are in the process of ordering and testing individual components. We will proceed with the final hardware-software integration when all components are fully tested.